How To Activate Rslogix 500

In this case, the PLC programming software would read the definition files and see that these addresses were already defined. The PLC symbol names and comments would be those defined from the drawing. In other words, you wouldn't be entering this information twice.

I have RESET the activation on the master disk, hoping to transfer it to the hard drive. But when I try to transfer, I get the message: ACTIVATION FILE CORRUPT - INVALID SERIAL NUMBER (This IS the master disk that came with the software before you ask!) I have no manuals or contact numbers here on site with me, can anyone help? If you lost the key from the hard drive, you won't be able to load another from the floppy until it is reset by Rockwell. I've done this before. They tell you where to find the files to delete, then give you a code number that will add one install to your floppy, then transferred to your hard drive. Your gonna have to call them in any case. By the way, I think you can use the floppy in the A: drive forever with AB.

Update: Rockwell recently extended access to the “temporary activation request form” to Machine & Equipment and Partner Level OEM's, as well as Recognized and Solution Partner System Integrators. They can now request their own 48 hour temporary activations primarily for use when visiting customer sites to make modifications, or for client demonstrations.

If an activation is on the wrong Master Disk, use A: EVMOVE (or A: EVMOVEW) on that disk to move it where you want it. If you find the activation on the wrong hard disk, use A: EVMOVE(W) on the right Master Disk to move it back to the Master Disk and then to where you want it. (Generally, that would be on the logical hard disk upon which you have installed the product.) Hope this helps! Larry Lawver Rexel / Central Florida. Assuming that yours are 'legal' copies of the software, have your 'master disks' physically on hand and a computer with a floppy drive fired-up and ready to go (not necessarily the computer that you'll be using for the RSLogix software). Then phone Rockwell Technical Support at 440-646-5800. Navigate the phone system menu for 'activation issues' (that's 3-2-1 at the time of this writing).

DOUBLE click on My Computer 2. RIGHT click on the drive that is the memory stick 3. LEFT click on properties 4. Under the General tab you can see the existing file format 5. It will be FAT or FAT32 6.

Frustrated, I tried upgrading from v16.03 t0 16.04 to see the newer minor rev. would resolve the issue, but it didn't. I then uninstalled and reinstalled v20.01 thinking v16 might have overwritten some important newer files, but this also didn't resolve the issue. Out of ideas, and a few hours lost to trial and error, I finally reached for the phone and called Rockwell Tech Support. However, following the universal “Murphy's law,” Rockwell's phone support had the day off! Before giving up, I made one last attempt at finding my answer on Rockwell's Knowledgebase. I decided to simplify my search as much as possible, using only two keywords in my search criteria: “16” and “activation.” Like clouds parting in the sky to let rays of light through, there at the very top of the search results was (public) Tech Note, which directly address the issue I was having. The Tech Note explains that when RSLogix 5000 version 16 won't activate while other versions do, the simple fix is to copy the “rsl5kcp.dll” file from the v17 program folder (C: Program Files Rockwell Software RSLogix 5000 ENU v17 Bin) to the v16 program folder (C: Program Files Rockwell Software RSLogix 5000 ENU v16 Bin) overwriting the v16 version of that file with the v17 version. Doing this immediately fixed my v16 activation issue.

> > I don't however wish to over emphasize file compatability problems. For > electrical schematics minor CAD format errors are normally not important. I > receive drawings in DXF format from several companies we deal with (they use > special electrical schematics software) and the problems have been > comparatively minor. > > > One final note on QCAD. There are two different QCAD programs from two > different sources.

This makes the task difficult even when two vendors are trying to interoperate. I don't however wish to over emphasize file compatability problems.

-- ************************ Michael Griffin London, Ont. Canada ************************. Hi Michael That last part is something that I had been thinking about for a while. Since we (for the most part) work with a symbolic language, how is a ladder editor that much different from CAD? Why should you have to draw your system twice? Once the proprietary barriers come down, the benefits from integration could be amazing. You don't offend me at all with your dislike for propped up monopolies.

This would include networked I/O (or other addressable content) as well as conventional local I/O. If you did your project in the ideal order, you would finish the drawings before you started the PLC program. In this case, the PLC programming software would read the definition files and see that these addresses were already defined. The PLC symbol names and comments would be those defined from the drawing. In other words, you wouldn't be entering this information twice. If the project involved some back and forth, that is changing the drawing after the PLC program was started, then the information would need to flow both ways.

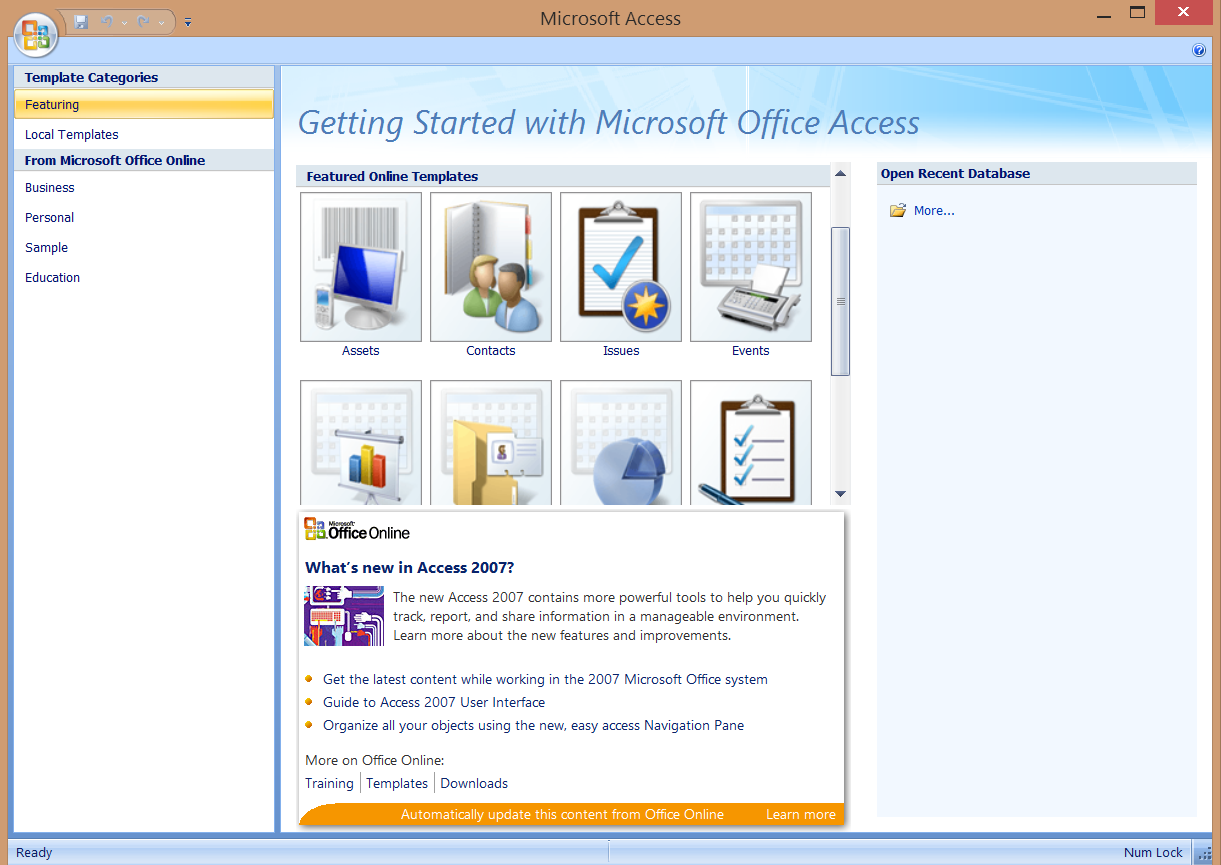

Download activation - Here, I can no longer click the button DOWNLOAD ACTIVATION. It was partly hidden(gray color in which i got stuck up).

That's a blast from the past! If the ZIP disk didn't have a file called EVMOVE.SYS on it (try enabling Windows to show System files) then it doesn't have an old-fashioned EVRSI activation. You can also try pointing the EVMOVECF.EXE utility (available from the RA Knowledgebase) at the ZIP disk.

If you really bought this from an individual it's more likely that you just need to fill out the transfer paperwork and use FactoryTalk Activation. Download and install the FactoryTalk Activation Manager software, and it will guide you through the process of choosing a hardware ID to use in conjunction with your product code and serial number to generate a *.LIC text file.

Hopefully if you're running into the same issue and struggled like me to find the correct knowbase doc, this blog will help you in find it quicker than search the knowbase directly. And if you have questions or have run into the same issue please feel free to share you comments with us by using the “post a comment or question” link below. Sincerely, Automation and If you enjoyed my article, you may like my courses. Yes – that sounds like what happened. But I’ve been able to get activations reset using Rockwell’s free online chat in under a couple of minutes, so you shouldn’t be without them too long. Keep in mind that the activation file is just a small text file which you can easily backup.

To actually use the stuff, you have to pay some money. And, as I keep bringing up, why is the trivial cost of PLC programming software any kind of an issue in a successful plant? Hope this helps! Larry Lawver Rexel / Central Florida. Hi Larry On February 17, 2004, ScienceOfficer wrote: > Curt--- > > We already went over your points in the longrunning thread, Why do you pay > for PLC programming software?, at > However, since this thread is actually about activations, note that the > automation industry experience with support for software without copy > protection is hideous. When an untrained end user purchases a second-hand > machine and wants support on the PLC, it's got to be paid for somehow.

To actually use the stuff, you have to pay some money. And, as I keep bringing up, why is the trivial cost of PLC programming software any kind of an issue in a successful plant? Hope this helps! Larry Lawver Rexel / Central Florida. Hi Larry On February 17, 2004, ScienceOfficer wrote: > Curt--- > > We already went over your points in the longrunning thread, Why do you pay > for PLC programming software?, at > However, since this thread is actually about activations, note that the > automation industry experience with support for software without copy > protection is hideous. When an untrained end user purchases a second-hand > machine and wants support on the PLC, it's got to be paid for somehow.

• Precede each search term with a '+', as follows: • +Modbus +TCP Otherwise, any post with either term will match. • Use double quotes around phrases, as follows: • +'Allen Bradley' +ethernetOtherwise, posts containing these words in separate locations will match.

If the project involved some back and forth, that is changing the drawing after the PLC program was started, then the information would need to flow both ways. If you addressed a new I/O point for an existing card in your PLC program, this would need to show up on the schematics. If the PLC software defined the device type, then this could appear directly on the drawing. If it was undefined, then this would appear as an undefined symbol in your drawings, and you would need to use the CAD software to complete the information. If you were to add a new I/O card or block, then either the CAD software would have to automatically insert a new page, or it would have to go into some sort of CAD limbo until you could deal with it properly. Perhaps both methods may be appropriate depending upon the type of device and how you want to handle things for that project.

It's funny that those who state that the software should come with the hardware miss two things. Software has to be purchased to use any PC.

In this case that was now version 16, which wouldn't let me past the activation screen. So the only quick way (I know of) to open any other version and bypass the activation popup was to launch RSLogix 5000 by double clicking on a different version ACD project file. As I expected, v20 launched with no issue. And since my first two steps indicated my FTA was working fine, I next tested creating new RSLogix 5000 files in the other versions I had installed. All worked except for version 16. Having isolated the problem to v16, I headed to Rockwell's Knowledge Base and began searching for a solution.

RA licenses are transferrable; I do this all the time with software we purchase, use for development and installation, then sell to our end customers. You just have to fill out a form transferring the license to the new owner. RA software is expensive and specialized and therefore very commonly pirated. For example, I have never seen a legitimate offer of RSI software on eBay. If you really bought this from an individual it's more likely that you just need to fill out the transfer paperwork and use FactoryTalk Activation.

> This is why many of the manufacturers have lost touch with their customers. -- ************************ Michael Griffin London, Ont. Canada ************************. Hi Michael Whoa there!

I had used the activation tool by selecting the GET NEW ACTIVATION on the menu. There were three steps given after clicking the GET NEW ACTIVATION on the left side menu: 1- Enter activation information-By giving my serial number and the product key(ok it displays the info of the product name). 2-Validate activation - It says your activation has been validated.

This is like being forced to buy a new car if you lose your car keys. -- ************************ Michael Griffin London, Ont. Canada ************************. When you're already buying a car with the hood welded shut:^) I've never understood their vehemence on this point either, What possible use would you have for their software if you didn't own their hardware? And if I owned 50 of their PLCs, I'm still not going to buy more than a couple seats. It would only make it much more convenient if I had more seats, Inconveniencing me isn't going to make them any more money. Overall, their programmer to PLC ratio is pretty low, I would think it would make sense to build the software cost into the hardware.

They couldn't sell that crap in it's current state. Rockwell Software doesn't make hardware. Rockwell Automation (Allen-Bradley, Reliance, & Dodge) do. Rockwell Software is a separate company and as such needs to turn a profit. They give it away, they don't stay in business. How many others in here work for a company that gives away it's chief products & services.

It is a conglomoration of NeXTSTEP, A/UX, and Mac OS 9. Mac os x 10.2 update download. It is based off the unix kernel and provides compatibility with X11.

And the burden of all that license management and support for all the related problems has to be fairly high as well. I would think widespread pirating of their software would demonstrably improve the market for their hardware. If they could just get over that absolute control thing. I might even buy a rack to work with at home if I didn't need $3000 to use it.

It would be very handy if the CAD software and programming (e.g. PLC and other) software could share a common symbol list. That is, when you add a device to a PLC output on an electrical schematic, it would show up automatically in the PLC program symbol list, and visa versa (or some convenient way of synchronising the two). A convoluted import/export function doesn't really accomplish the same thing, as it doesn't accomodate design changes mid way through a project very well. For this to work well though, the CAD and PLC software vendors would have to be willing to swallow the idea of open data formats, and I haven't seen any evidence of that yet.

Hi all, I have a bit of a problem here this morning, I have been called to a job, at a site I have not attended for over 8 months, to look into a 'program' fault with one of the machines. On starting up RSLogix 500 I was greeted with the message: FATAL ERROR! THE COPY PROTECTION LICENSE FOR THE APPLICATION COULD NOT BE ACQUIRED. ERROR: 2 After much head scratching, I can only imagine that the IT dept. Have been doing a disk cleanup or something (no one else has access to this PC).

File format translation (including to DXF) often introduces artifacts into the drawings which require you to fix up the translated drawings manually. This causes problems when exchanging drawings between companies (e.g. Supplier and customer) unless they are in the same format. I have owned other CAD software in the past, but Autodesk's means of dealing with low priced competition has been to buy up the companies and terminate their products.

Are there serious contenders out there? I haven't seen too many.

I would have to disagree with you completely on this point, and say that this is in fact a very accurate description of their product. The only people I know of who are still using AutoCAD are using it for electrical schematics. It used to be widely used for mechanical drafting, but I don't know of anyone who is still using it for this. Competitors such as Solidworks are considered by most people to be vastly superior to anything AutoCAD has to offer. > If they could > come to understand that and lower their prices, open their formats and > support the fact that an awful lot of workstations users have no > interest in MS crashware for simulations, etc. That may run for weeks > at a stretch, I think they could stand on merit. AutoCAD simply isn't good enough for large scale simulations, besides which those types of applications run on Unix/Linux clusters, not Windows desktops.